CNC Engraving Machine for Marble Stone Granite

Description

Basic Info

| Function | Cutting, Line Engraving, Lettering |

| Application Material | Marble |

| Automation | Automatic |

| Control | CNC |

| Motor Power | High Power |

| Engraving Head Speed Adjustability | Wide Adjustable Range |

| Certification | CE, ISO |

| Current | AC |

| Application | Ceramics, Decoration, Advertising, Art & Craft, Stela & Gravestone, Stone Industry |

| Customized | Customized |

| Spindle Rate | 5.5kw |

| Working Table | Aluminum T-Slot Table with Stainless Steel Water T |

| Mechanical Precision | 0.02mm |

| Software | Artcam Software |

| Control System | Nk105 |

| Spindle Speed | 0 - 24, 000rpm/Min |

| Driving Motor | Stepper Motor |

| Guide Way | Imported Hiwin Square Rail From Taiwan |

| Transport Package | Standard Export Woode Case |

| Specification | 1300*2500mm |

| Trademark | APEXCNC |

| Origin | Jinan |

| HS Code | 84649012 |

| Production Capacity | 100 Pieces/Month |

Product Description

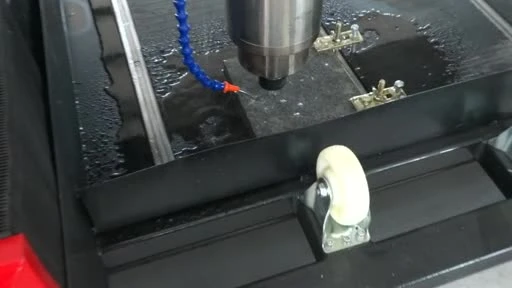

CNC Engraving Machine for Marble Stone Granite

Product DescriptionIt is mainly used in engraving stone, marble, granite, black stonge, bluestone, jade stone, crystal, glass, organic glass Floor tile and ceramic tile, plastic, chemical synthesis board, PVC board, bamboo ware, aluminum-plastic panel, metal, etc., line carving, 2D engraving, 3D engraving, 3D relief, Cutting, drilling, polishing, etc.

1. Features:1) Spindle: China best brand CS 5.5kw water cooling spindle , which guarantees the high working speed, accuracy, rotating precision.

2) Inverter: Fuling Inverter or Delta Inverter is optianal, it guarantees the high working speed and accuracy, and engraves without any ripple, but with smooth bottom level and clear outline.

3) Motor: Servo motor and stepper motor is optional, which guarantees the positional accuracy.4) Driver: For stepper motor, Leadshine bigger driver; For servo motor, use matching driver. It can supply a steady stream power for motor.5) Guide Rail:Taiwan Hiwin linear rail, self-lubricating sliding block. It ensures equal force in all directions and accuracy and strength of the machine.

6) Screw Transmission:Taiwan HIWIN screw transmission, it has high efficiency,sensitivity, positioning accuracy, long life.7) Rack: Using Helical rack and pinion transmission, it has higher accuracy.8) Control system: Use NK105 DSP controller, with stable and easy operation. ( NC Studio, mach3 can be choosed)9) France Schneider contactor and leakage protector, protect the machine circuit well during the working.10) High soft cables, tens of thousands of bending without damage.11) Lathe bed is of high quality by cast steel, after re-treatment, much stronger and more stable. Aluminum table +PVC+ sink.12) Mist-cooling system, prevent stone chips radiance when processing.

Descriptions of stone engraving machine:

Description | Parameter |

X,Y,Z Working Area | 1300mmx2500mmx300mm |

Table Size | 1450mm×2940mm |

Table Surface | T-slot Table |

Frame | Thicker Welded Steel tube Structure |

Spindle Power | 5.5KW water cooling spindle |

Spindle Speed | 0-24000RPM |

Motors | 450B stepper motors ( 4 sets in total ) |

Driver | Leadshine driver |

Transmission | X,Y Axis: Helical Rack and Pinion DriveZ Axis: Taiwan TBI ball Screw |

Machine Guide Rails | Taiwan Hiwin Linear square guide rail |

Inverter | Fuling Inverter |

Operating System | N105 DSP control system |

Soft Limit switch | Japan Omron limit |

AC contactor | France Schneider |

X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

X,Y,Z Repositioning Accuracy | ±0.03mm |

Max. Rapid Travel Rate | 33000mm/min |

Max. Working Speed | 25000mm/min |

Max. Power Consumption | 7KW(Without Spindle) |

Working Voltage | AC380V/50Hz, 3Phs (Option: 220V) |

Command Language | G Code |

Computer Interface | USB |

Collet | ER25 |

Software Compatibility | Artcam OR Type3 Software |

Running Environment Temperature | 0 - 45 Centigrade |

Relative Humidity | 30% - 75% |

Packing Size | 3300mm*2100mm*2300mm |

N.W. | 1450KG |

G.W. | 1680KG |

Optional Parts | Motor and Driver: Servo systemJapan: Yaskawa / Panasonic servoChina: Taiwan Delta servo |

Control system: NC Studio/Syntec/mach3 |

Application:

1. Stone industry: apply to 3D relief, thread sculpture, cutting, drilling 2D engraving on all kinds of materials, such as natural marble, granite, artificial stone, tombstone, milestone, ceramic tile, glass and other materials 2 Woodworking industry: apply to door, windows, cabinet, craft door, paint-free door, screen, wave board processing, 3. Advertisement industry: apply to processing all kinds of design of rich and colorful model, Such as labels. architectural molds, badge, engraving plate . exhibition boards, doorplate. Direction board, decoration and so on.4. Handcraft industry: apply to engraving patterns and characters on all kinds of materials , such as wood,bamboo, marble , organic board, double color board.5. Other industry: Relief carving, photograph craving, openwork engraving, plane engraving, cutting and milling bottom etc.

If you have specific requirement for CNC stone engraving machine, customized is available.

Jinan Apex Machinery Equipment is a comprehensive enterprise who is devoted to manufacturing cnc router, laser engraving machine, laser marking machine, plasma cutting machine, stone carving machine.

All products have to pass strict inspection before delivery, and applied the CE, ISO, certificate if the clients must need. Factory covers about 3000 square meters, including R&D center. It has about 300 staffs, 10 engineering experts and 18 technical engineers included, After years of continuous efforts and clients supporting till nowadays, it has developed a working system model of design, production, trade one stop service. The new and existing customers are spreading throughout the South America,Middle East, Southeast Asia, Africa, Europe and other Counties and places.

Welcome friends world widely come to visit and expect further continuous support please.

1) Two years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge when if any problem during the warranty period.

2) Lifetime maintenance free of charge.

3) 24 hours on line service each day, free technical support.

4) Machine has been adjusted before delivery.

5) Provide the whole life after service.

FAQQ1.How can i get the machine?

CIF:Almost finish production →order shipment and confirm shipping date→delivery machine to portof loading→declare at customs→shipping→delivery to port of destinationFOB:Almost Finish production→tell us your shipping agent contacts and confirm shipping date→delivery machine to port of loading→declare at customs→shipping→delivery to port of destinationDDP:Almost finish production →order shipment and confirm shipping date→delivery machine to port of loading→declare at customs→shipping→delivery to port of destination-clearance-delivery machine to your placeQ2.Why choose us?We provide you a solution and not just a machine.Well configured machine using hardware that makes the machine efficient, accurate, and reliable.Feel Confident when buy from a CNC company that has expert staffs with over 10 years of CNC building experience.Get the support that you deserve from our confident well trained staff members.iGolden prides itself in having the patience and the ability to provide knowledge and service. Q3. How to choose the most suitable machine?Kindly let us know the following details:1.What is your Max.working area?2.What material will you work on?3.Do you mainly engrave or cut? If cut,What is your Max.cutting thickness?4.You also can send your product samples to us.According to your sample,we will recommend the best suitable machine for you

Our Contact