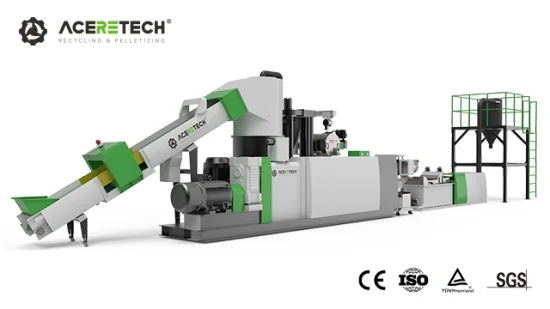

Professional Service Good Price Plastic Recycling Machine Waste

Description

Basic Info

| Model NO. | ACS-PRO |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Ceramic Heater or Far-Infrared Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008, TUV |

| Condition | New |

| Machine Type | Plastic Recycling Pelletizing Machine |

| Voltage | 380V 50Hz or Customized |

| Electric Components | ABB, Ls, Omron, or Customized |

| Application | Film, Filament, Raffia, Foam |

| Compacting Room Size | 800L-2800L |

| Capacity Range | 320kg/H-2100kg/H |

| Target Being Recycled Material | PE, PP, PS, ABS |

| Control | P.L.C Control |

| Sample/Service Manua | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| After-Sale Service | Free Spare Parts |

| Final Product | Pellets/Granules |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Material | Iron |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477209000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kgProduct Description

Professional Service Good Price Plastic Recycling Machine WasteProduct Description

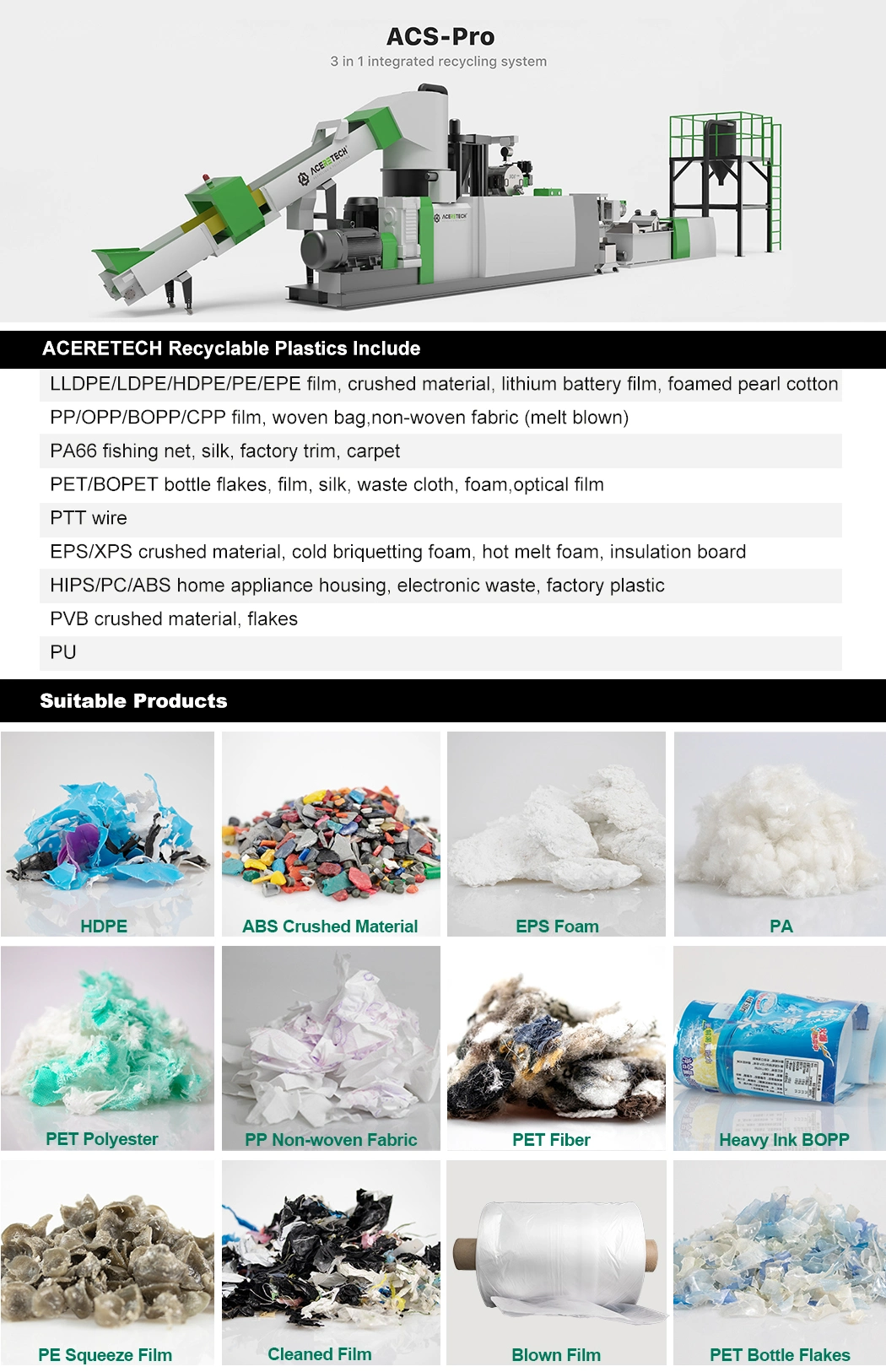

Suitable for high impurities materials. Instead of two stage machine.ACS-H Pro compacting and pelletizing system:The new recycling and granulation system is equipped with an optimized design single screw extruder and filtered in front of the vacuum degassing area. It is especially suitable for heavy printed or polluting plastics.Application: PE,PP,PS,ABS

Product Parameters

SPECIFICATIONS | |

Machine Model | ACS-Pro |

Target Recycled Material | HDPE,LDPE,PP,BOPP,CPP,OPP,PA,PC,PS,PU,ABS,PET |

Final Product Shape | Particles |

System composition | Belt Conveyor, Air Exhausting Device, Sliding Gate, Cutting Compactor with Inverter, Single Screw Extruder, Filtration first,Vacuum Degassing, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo. |

Output Range | 320kg/h-2100kg/h |

Feeding Device | Belt Conveyor (Standard), Roll Hualing off device (Optional) |

Compactor Volume | 800L-2800L |

Diameter of screw | 100mm-180mm |

Material of screw | Bimetal |

L/D of screw | 50/ 1 |

Heater of barrel | Ceramic heater or Far-infrared heater |

Cooling of Barrel | Air cooling of fans through blowers |

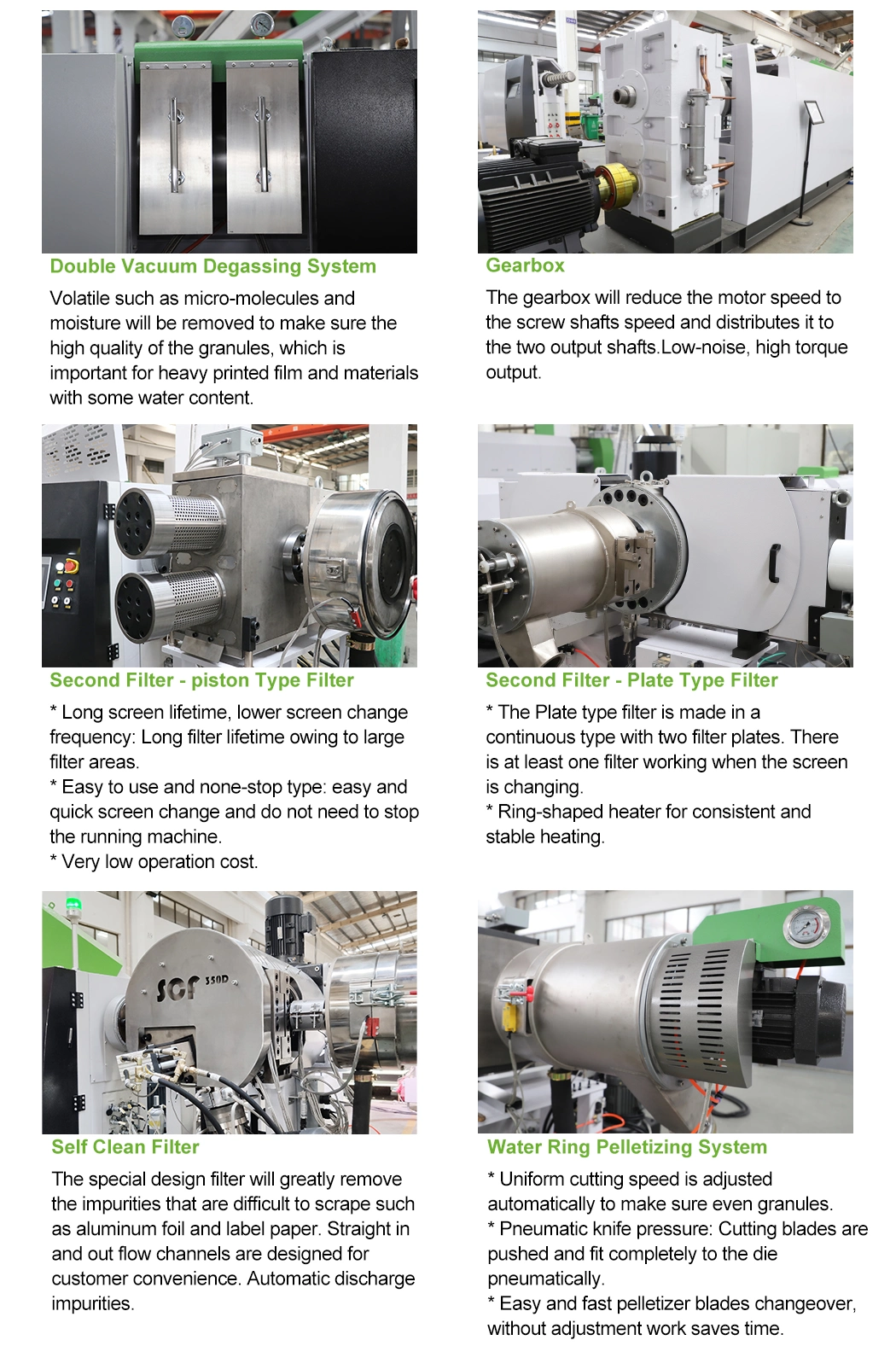

Vacuum deashing exhaust | Two Double-zone vacuum degassing system (Standard) |

Pelletizing type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing |

Voltage Standard | According to the Voltage of the Customer's Location |

Optioanl device | Metal detector, Roll hualing off device, Masterbatch and additives feeder |

Warranty | 13 months from the date of bill of lading |

Technical services | project design, factory construction, installation and recommendations, commissioning |

| Model | Compactor Volume (L) | Screw diameter(mm) | L/D ratio | Productivity(kg/h) for LDPE/LLDPE | Productivity(kg/h) for BOPET/PET |

| ACS-PRO1008 | 800 | 100 | 50 | 400-500 | 500-600 |

| ACS-PRO1414 | 1400 | 140 | 50 | 900-1000 | 900-1150 |

| ACS-PRO1616 | 1600 | 160 | 50 | 1300-1500 | 1200-1600 |

| ACS-PRO1828 | 2800 | 180 | 50 | 1800-2000 | 1800-2100 |

Detailed Photos

Company Profile

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

Prev: Acs-PRO Plastic Recycling PP/PE Film Pelletizing Extruder Machine with Compaction Crushing Silo

Our Contact