High Productivity Plastic Recycling Pelletizing Machine

Description

Basic Info

| Model NO. | ACS-PRO |

| Screw | Single-Screw |

| Inverter | Inverter |

| Electromagnetic Heater | Ceramic Heater or Far-Infrared Heater |

| Automation | Automatic |

| Computerized | Computerized |

| Customized | Customized |

| Certification | CE, ISO9001:2008 |

| Condition | New |

| Machine Type | Recycling Machine |

| Voltage | 380V 50Hz or Customized |

| Electric Components | ABB, Ls, Omron, or Customized |

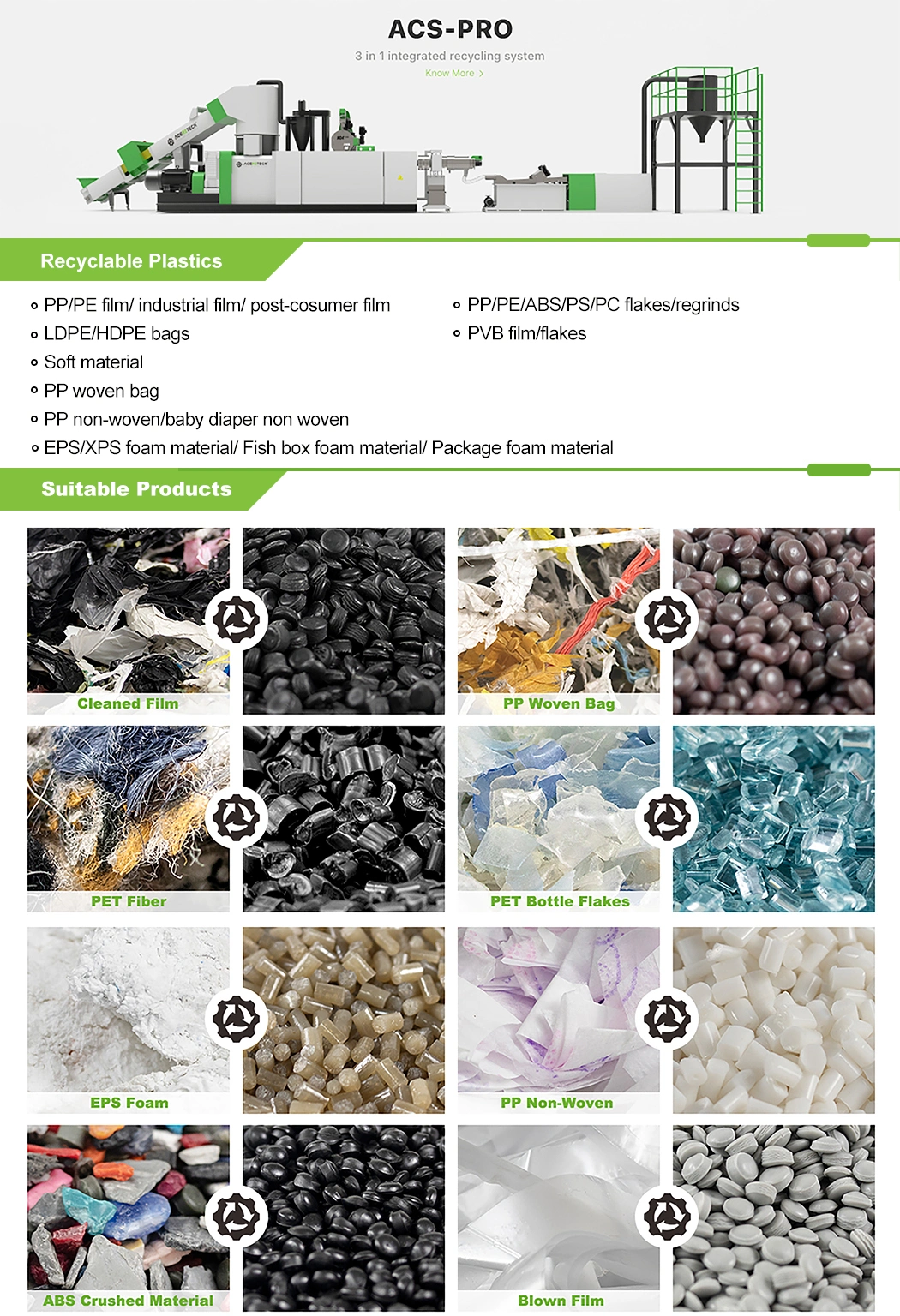

| Application | Film, Filament, Raffia, Foam |

| Compacting Room Size | 800L-2800L |

| Capacity Range | 320kg/H-2100kg/H |

| Target Being Recycled Material | PP PE Pet ABS PS PC |

| Control | P.L.C Control |

| Sample/Service Manua | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| After-Sale Service | Free Spare Parts |

| Final Product | Pellets/Granules |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Material | Iron |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477209000 |

| Production Capacity | 100sets/Year |

Packaging & Delivery

Package size per unit product 500.00cm * 200.00cm * 200.00cm Gross weight per unit product 2700.000kgProduct Description

High Productivity Plastic Recycling Pelletizing MachineProduct Description

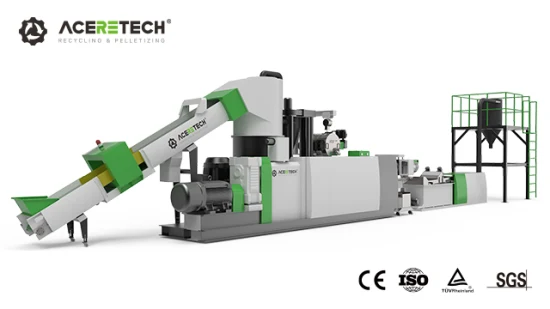

ACS -PRO Compacting and Pelletizing Machine

To meet the market demand, ACERETECH developed and launched environmental 3 in 1 integrated plastic granulation recycling system--ACS-PRO COMPACTING AND PELLETIZING MACHINE, which is excellent degassing and filtering performance for recycling.It is different from traditional granulation line.This ACS-PRO is the entirely new standard recycling and pelletizing system with optimized super long L/D ratio, filtering ahead of vacuum degassing, specially suit to the waste plastics such as high contaminated and heavily printed recycling and pelletizing..

Machine Working Process:

The equipment includes the belt conveyor/ hauling off feeding device, compactor, single screw extruder ,middle filtering system, double zone vacuum degassing system, second filter system, water-ring pelletzing system/ under-water pelletizing/ water strands pelletizing system/ under water strands pelletizing system, dryer, product silo and electric cabinet control system.

With well understanding of characteristics of different plastic materials and modular design, ACS-PRO pelletizing machine optimizes size-reduction and pre-heating precess in the compactor, avoids over-heating or degradation. The drive of compactor contolled by inverter, together with sliding gate device installed on the outlet of compactor room, to guarantee ACS-PRO not only handle loosing material recycling but also rigid regrinds material re-pelletizing.

Product Parameters

SPECIFICATIONS | |

Machine Model | ACS-Pro |

Target Recycled Material | HDPE,LDPE,PP,BOPP,CPP,OPP,PA,PC,PS,PU,ABS |

Final Product Shape | Particles |

System composition | Belt Conveyor, Air Exhausting Device, Sliding Gate, Cutting Compactor with Inverter, Single Screw Extruder, Filtration first,Vacuum Degassing, Pelletizer, Water Cooling Device, Dehydration Section, Conveyor Fan, Product Silo. |

Output Range | 320kg/h-2100kg/h |

Feeding Device | Belt Conveyor (Standard), Roll Hualing off device (Optional) |

Compactor Volume | 800L-2800L |

Diameter of screw | 100mm-180mm |

Material of screw | Bimetal |

L/D of screw | 50/ 1 |

Heater of barrel | Ceramic heater or Far-infrared heater |

Cooling of Barrel | Air cooling of fans through blowers |

Vacuum deashing exhaust | Two Double-zone vacuum degassing system (Standard) |

Pelletizing type | Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing |

Voltage Standard | According to the Voltage of the Customer's Location |

Optioanl device | Metal detector, Roll hualing off device, Masterbatch and additives feeder |

Warranty | 13 months from the date of bill of lading |

Technical services | project design, factory construction, installation and recommendations, commissioning |

| Model | Compactor Volume (L) | Screw diameter(mm) | L/D ratio | Productivity(kg/h) for LDPE/LLDPE | Productivity(kg/h) for BOPET/PET |

| ACS-PRO1008 | 800 | 100 | 50 | 400-500 | 500-600 |

| ACS-PRO1414 | 1400 | 140 | 50 | 900-1000 | 900-1150 |

| ACS-PRO1616 | 1600 | 160 | 50 | 1300-1500 | 1200-1600 |

| ACS-PRO1828 | 2800 | 180 | 50 | 1800-2000 | 1800-2100 |

Detailed Photos

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

Prev: Low Price Continuis Plastic Recycling Machine

Next: Immediate Delivery PP Baby Diaper Non Woven Waste Plastic Recycling Pelletizing Extruder Machine

Our Contact